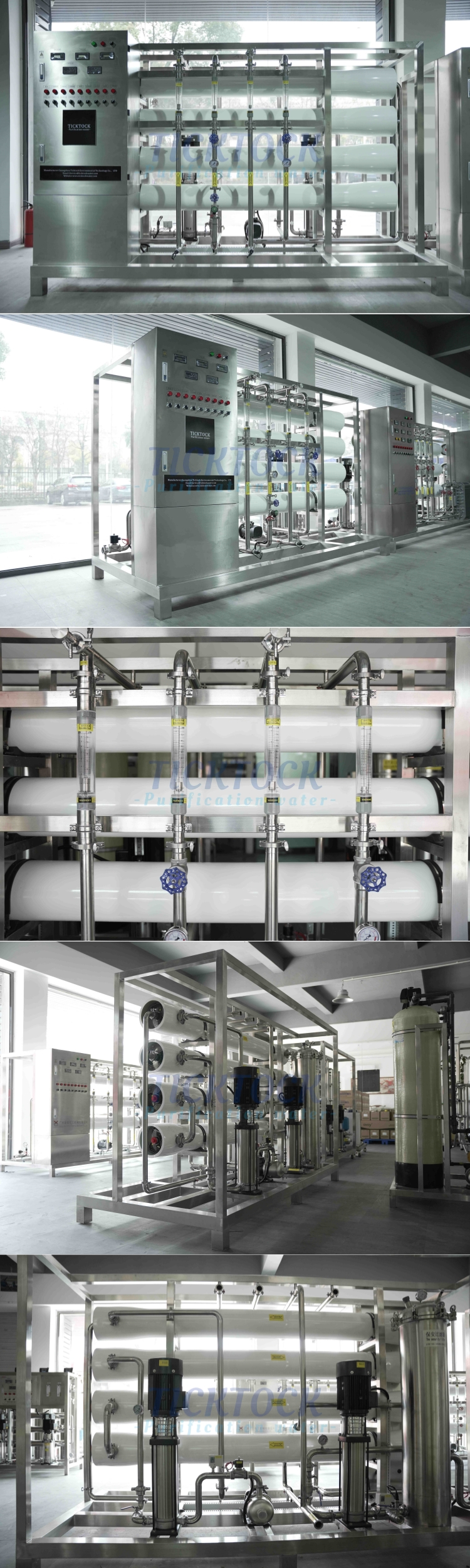

3 Tons Per Hour Dual-Stage Reverse Osmosis Equipment Product Introduction

The 3 tons per hour dual-stage reverse osmosis (RO) system is a high-efficiency water purification solution designed for industrial and

commercial applications requiring ultra-pure water. Combining advanced membrane technology and automated controls, this system

ensures stable operation, energy efficiency, and compliance with stringent water quality standards.

Core Features

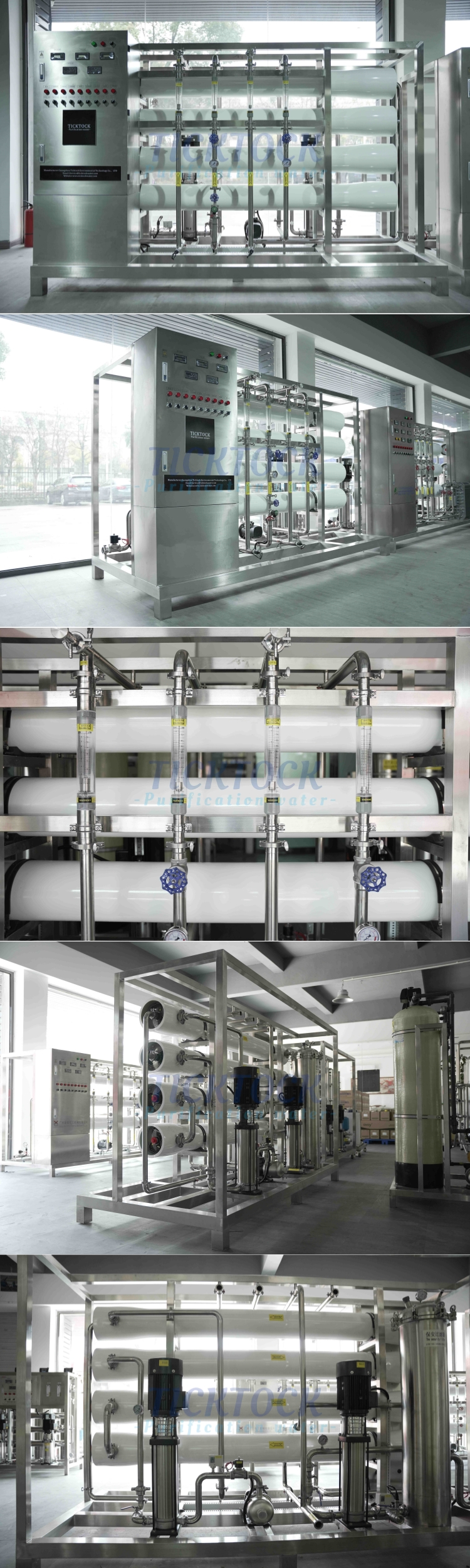

1. Dual-Stage RO Design

The system utilizes two stages of reverse osmosis membranes (e.g., BW30-4040 or similar models). The first stage removes up to 98% of

dissolved salts, colloids, and organic impurities, while the second stage further reduces residual ions, achieving a resistivity

of up to 18 MΩ·cm. This dual-stage process guarantees water purity suitable for electronics, pharmaceuticals, and high-end

material processing.

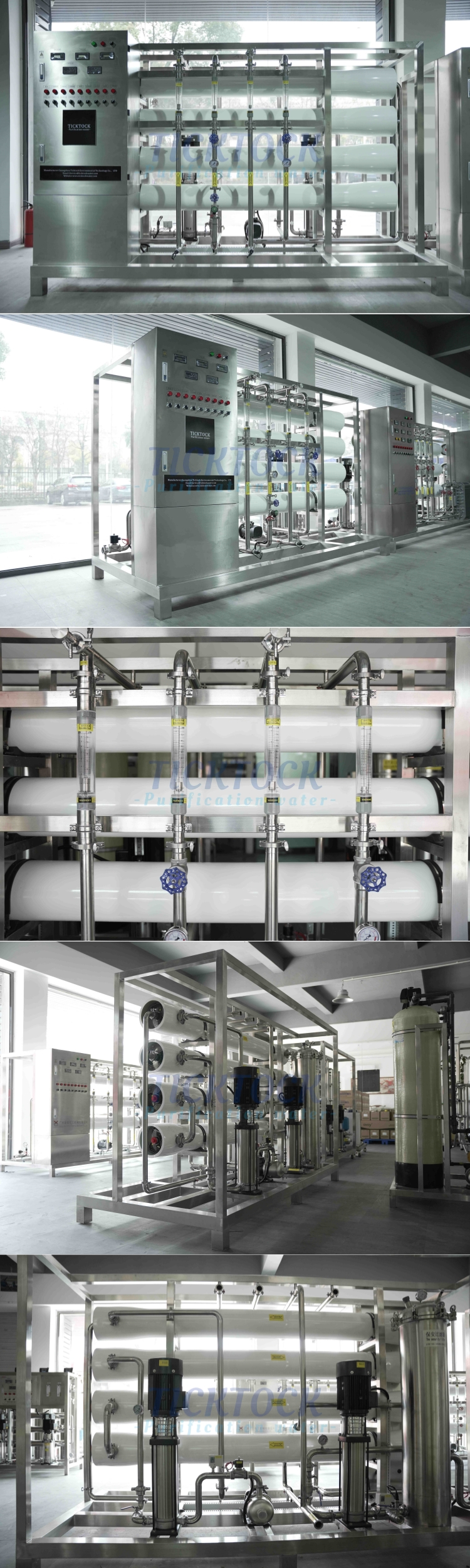

2. Comprehensive Pretreatment

A robust pretreatment system includes quartz sand filtration, activated carbon adsorption, and precision filtration (5μm) to eliminate

suspended solids, chlorine, and organic contaminants. An automatic dosing system injects scale inhibitors to prevent membrane

fouling, ensuring long-term membrane durability.

3. Automated Operation

Equipped with PLC control and pressure sensors, the system enables one-touch startup, real-time monitoring of parameters (pressure,

flow rate, TDS), and automatic alarms for abnormal conditions. The integrated high-pressure pump (5.5 kW, 15 bar) optimizes energy

consumption while maintaining consistent output.

4. Compact and Durable Structure

The modular design minimizes footprint, and components like stainless steel or FRP pressure vessels enhance corrosion resistance. UV

sterilization or ozone treatment can be added post-RO to ensure microbial safety.

Applications

– Industrial Use: Boiler feed water, semiconductor manufacturing, and chemical processes.

– Drinking Water: Municipal or community pure water supply compliant with GB17324-2000 standards.

– Wastewater Reuse: Desalination and recycling of industrial wastewater.

Maintenance and Service

Regular membrane cleaning (every 240 operational hours) and replacement of filter media (e.g., quartz sand every 2,900 hours) are

recommended. The system includes a CIP (Clean-in-Place) module for easy maintenance.

With its high automation, reliability, and adaptability to diverse water sources, this 3-ton dual-stage RO system is an ideal choice

for achieving sustainable water resource management and operational cost efficiency.

https://www.youtube.com/@ticktockwater

https://www.youtube.com/@ticktockwater

https://www.youtube.com/@ticktockwater

https://www.youtube.com/@ticktockwater

https://www.youtube.com/@ticktockwater

https://www.youtube.com/@ticktockwater